| Min. Order: | 100 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, WU, T/T, Paypal |

| Place of Origin: | Zhejiang China(Mainland) |

| Means of Transport: | Land, Ocean, Air |

| Production Capacity: | 5000 Sets Per Month |

| Packing: | Blow Box |

| Delivery Date: | 30 Days | Model No:: | LT6196 |

|---|---|---|---|

| Color: | Red/Blue/Black | Port: | Ningbo/Shanghai |

| Pricing Term: | FOB | Delivery Time: | 30 Days |

| Payment Term: | L/C,T/T,Paypal | Transport: | Sea,Air,Land |

Description:

Comprehensive kit for the removal and installation of oil seals without damaging the new seal or housing.

Kit includes a seal removal puller and seven adaptors to fit most sizes of seal.

Designed to allow original pulley/flange bolt to be used to press in the new seal, ensuring a squarely seated seal every time.

Contents:

1×Puller

2×Seal Hooks

7×Seal Adaptor

7×Bolt Adaptors

4×Spacers

1×Installer Plate

Specification:

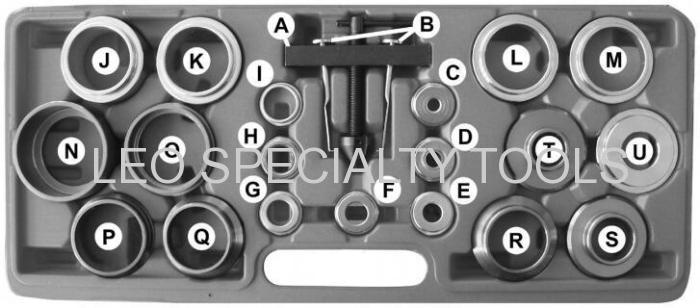

Item No. | Description | Item No. | Description |

A | Puller | L | Spacer 18mm |

B | Seal Hooks | M | Spacer 10mm |

C | Bolt Adaptor 8mm | N | Seal Adaptor 64mm |

D | Bolt Adaptor 10mm | O | Seal Adaptor 56mm |

E | Bolt Adaptor 12mm | P | Seal Adaptor 49mm |

F | Bolt Adaptor 14mm | Q | Seal Adaptor 46mm |

G | Bolt Adaptor 16mm | R | Seal Adaptor 42mm |

H | Bolt Adaptor 18mm | S | Seal Adaptor 34mm |

I | Bolt Adaptor 20mm | T | Seal Adaptor 28mm |

J | Spacer 27mm | U | Installer Plate |

K | Spacer 22mm |

Removing old seal.

1.Remove pulley as per proprietary manual.

2.Insert the seal hooks into the inner edge of the seal 180° apart.

3.Insert the legs of the hooks into the arm of the seal puller, screw down and seat the puller force screw into the end of the shaft.

4.Screw in the force screw to remove the oil seal.

Installing new seal

1.Take an appropriately sized bolt adapter and insert it into the installer

plate.

2 When the shaft protrudes a distance from the block/head a spacer has to be used. Any combination of the 4 different length spacers may be needed to ensure the bolt can be screwed in enough to seat the seal.

3.Finally use a seal adaptor that is relative to the size of the seal.

4.Slide the oil seal and installation assembly over the shaft and screw the pulley bolt into the shaft through the bolt adaptor.

5.Screw in the bolt ensuring the oil seal is square as it is compressed into the seal housing. Continue to tighten the bolt until the oil seal if seated fully.