| Min. Order: | 100 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, WU, T/T, Paypal |

| Place of Origin: | Zhejiang China(Mainland) |

| Means of Transport: | Land, Ocean, Air |

| Production Capacity: | 5000 Sets Per Month |

| Packing: | Blow Box |

| Delivery Date: | 30 Days | Model No:: | LT6267 |

|---|---|---|---|

| Color: | Red/Blue/Black | Port: | Ningbo/Shanghai |

| Pricing Term: | FOB | Delivery Time: | 30 Days |

| Payment Term: | L/C,T/T,Paypal | Transport: | Sea,Air,Land |

Product Features:

Bearing extractor collects with internal capacity from 10 to 32mm;

Fully chromed carbon steel medium stroke slide hammer, 380mm overall length with 940 gram hammer

Blow moulded plastic case keeps all the tools organized and easy to transport;

Product Specification:

This professional inner bearing puller set come with 1 slide hammer and 4 Sizes of attachment;

One fully chromed carbon steel medium stroke Slide Hammer;

Four chrome molybdenum steel made attachment:

10 to 14mm Attachment;

15 to 19mm Attachment;

18 to 25mm Attachment;

25 to 32mm Attachment;

This internal puller can pull out the bearing without damaging any of the surrounding parts, just simply open the clamps by turning the handle clockwise so that it is snug against the bearing and pull out by sliding the weight backwards. Ideal for the auto body repairer or the home garage DIY user.

INSTRUCTIONS:

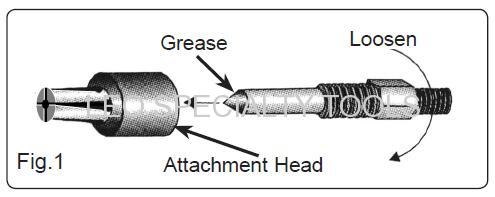

Prior to use of the required attachment,disassemble and grease as shown in fig.1. Reassemble the attachment.

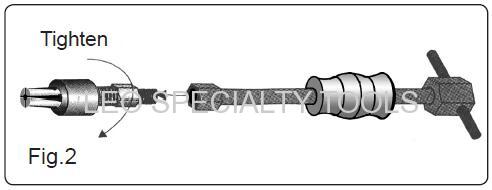

2. Screw the attachment into the shaft, as shown in fig.2. Tighten the attachment using a wrench.

Note: Do not over tighten.

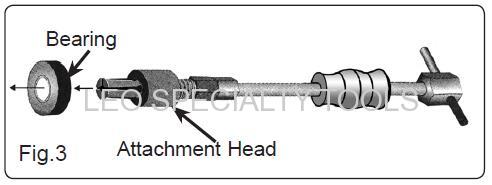

3. Ensure the attachment jaws are completely closed and insert the attachment into the inner diameter of the bearing, fig.3.

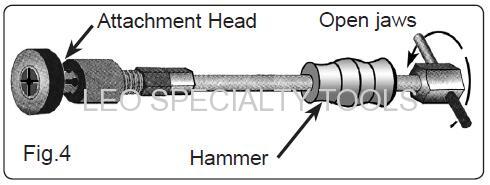

4 Turn the handle clockwise to open the attachment jaws to grip the bearing. See fig.4.

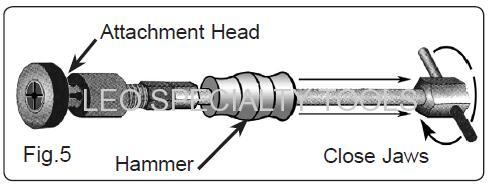

5. Hold the bearing puller as shown in fig.5, slide the hammer to the bearing end of the shaft and then forcefully pull the hammer to the other end of the shaft.

6. Ensure the bearing is being pulled out evenly, if not, remove the puller attachment and, using a soft faced mallet, tap the bearing until it is seated evenly.

7. Turn the handle anticlockwise to close the jaws in order to release the bearing from the attachment head. See fig.5.

Packing details:

QTY(SET) | G.W.(KGS) | N.W.(KGS) | MEAS(CM) |

4 | 13 | 12 | 40*34*33 |