| Min. Order: | 100 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, WU, T/T, Paypal |

| Place of Origin: | Zhejiang China(Mainland) |

| Means of Transport: | Land, Ocean, Air |

| Production Capacity: | 5000 Sets Per Month |

| Packing: | Blow Box |

| Delivery Date: | 30 Days | Model No:: | LT6209 |

|---|---|---|---|

| Color: | Red/Blue | Port: | Ningbo/Shanghai |

| Pricing Term: | FOB | Delivery Time: | 30 Days |

| Payment Term: | L/C,T/T,Paypal | Transport: | Sea,Air,Land |

Description:

For repairing the guide pin threads in the wheel bearing housing especially for VAG vehicles.

With disassembly of guide pins while changing the brake pads the internal threads are frequently destroyed.

The defective threads are repaired professionally and quickly with a heavy duty rustproof high-grade steel threaded bush.

Application Range: Audi A3 (Type 8L), VW Golf 4, VW Bora, VW Passat (since 2003), VW Polo, ?koda Octavia, Seat Leon, and others.

Content:

1 Special core drill

1 Special tap M12 x 1.5

1 Positioning bar VAG Group

10 Replacement bushes with copper ring M12 x 1.5

Introduction:

Quick and effective method of replacing brake calliper threads using M12 inserts. Stepped drill allows oversizing of the hole, allowing insert to be fitted. Features one alignment plate for precision drilling for new insert. Kit includes M12 tap, step drill, insert locator, two washers with centre roller bearing and ten replacement inserts in storage case.

Specification:

Calliper Insert Thread Size:M12x1.5mm

Ref. | Description |

1 | Insert Locator |

2 | Washers and Roller Bearing |

3 | M12 Tap |

4 | Step Drill |

5 | Alignment Plate |

6 | Threaded Inserts (Replacment Insert - Pack of 10) |

Instruction:

1.Remove the road wheel, brake disc and brake calliper from the vehicle. Next remove the calliper mounting bracket, in some vehicles the calliper mounting bracket is a cast part of the hub.

2. Clean up the calliper mounting bracket and mount it in a vice.

3. One Thread Stripped.

3.1 Clean the thread that is still intact using the M12 tap. Grease the tap for lubrication.

3.2 Screw the insert locator (fig.1.1) into the good thread then slide the alignment plate over the locator.

3.3 Using the other hole on the alignment plate as a guide, drill out the damaged thread using the stepped drill bit (fig.1.4). Continue drilling all the way through, using the larger diameter on the drill bit to enlarge the bolt hole so a threaded insert can be used.

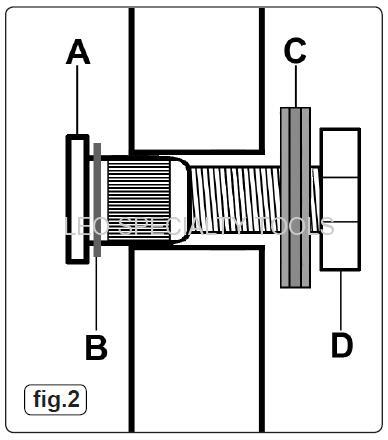

3.4 Take a threaded insert (fig.1.6) with copper washer and insert into drilled out hole. Ensure it is pushed in the opposite end that the bolt is inserted (fig.2A).

Note: Use some thread lock on the threaded insert.

3.5 Slide the washers and roller bearing (fig.2C) over the calliper bolt then insert into the drilled out hole then screw into the new insert. Tighten the locator to seat the new insert fully home.

3.6 Remove the bolts and reassemble the brake calliper onto the vehicle, refer to a proprietary manual for correct procedure.

4. both Threads Stripped.

4.1 When both threads are damaged use the stepped drill bit to centre on the first hole.

4.2 Follow from 3.4 inserting a threaded insert.

4.3 Then follow from section 3.2 for the second hole.

Packing details:

QTY(SET) | G.W.(KGS) | N.W.(KGS) | MEAS(CM) |

10 | 12 | 11 | 54*25*18 |